"Time to breathe out - We don't like cold air in our boiler in the morning, lets see how we clear it."

If you have ever worked a very old machine, you will have noticed that when you started the machine up the first thing in the morning, and then patiently awaited for it to reach operating temperature, that the first time you operated the steam valve, all you got was a gush of cold air, and then you had to wait around again for the machine to heat up. Trying to ignore the irate customers!

Having to vent the machine the first thing before service was caused by the boiler dropping in pressure over night and the remaining steam causing a vacuum. When you first then switched the machine on, this positive vacuum made the pressure switch think it was up to temperature.

Lucky for you, the manufactures solved this little problem.

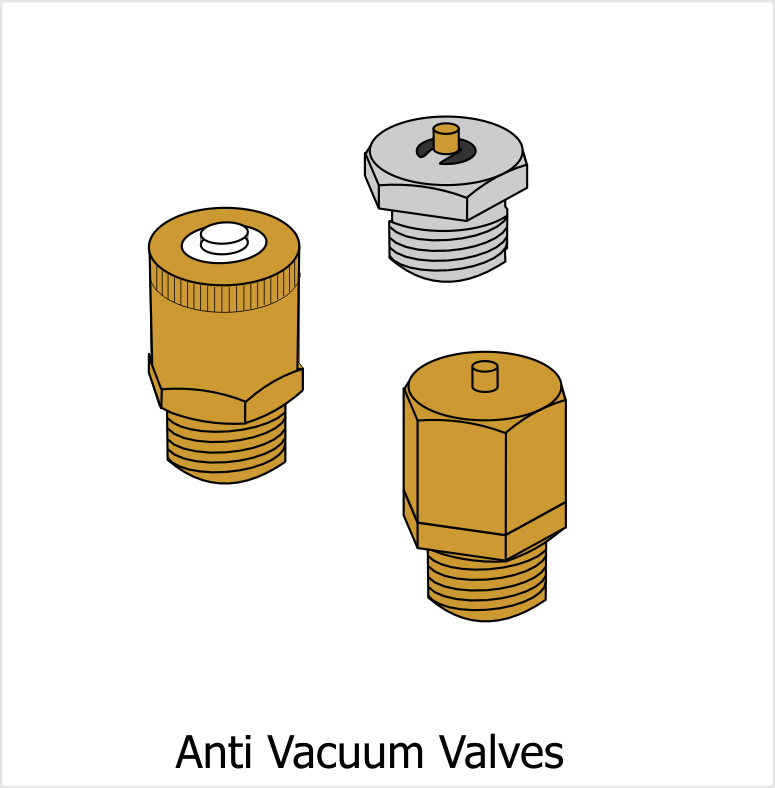

They came up with a simple little device called the Anti Vacuum Valve, that vented the boiler during the night as the the machine cooled down, and then as the pressure built up in the boiler, the valve closed itself.

As with all things, they do come in various shapes and sizes, some very high end machines might use an electrical valve to vent the machine.

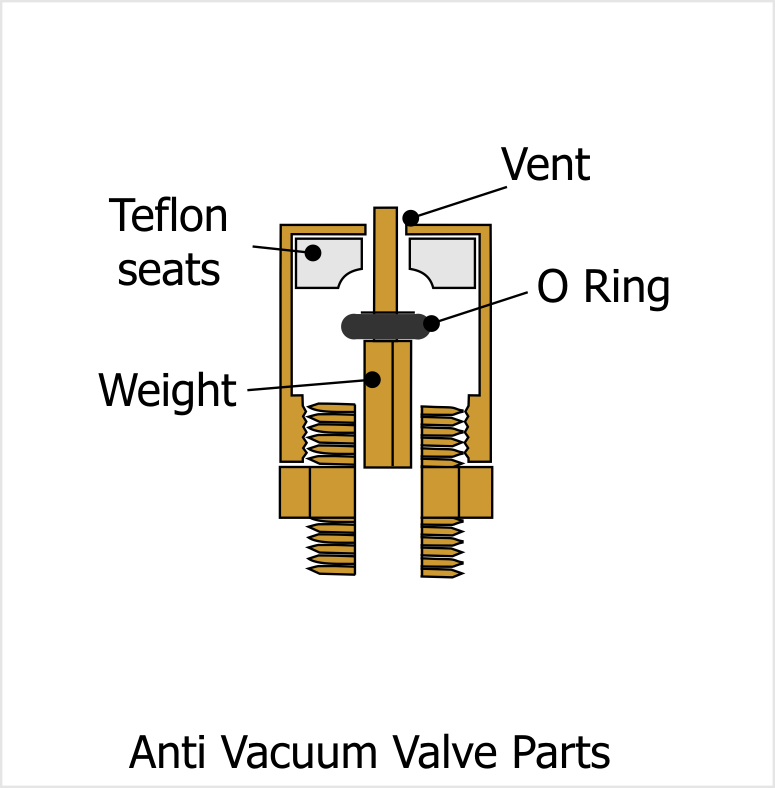

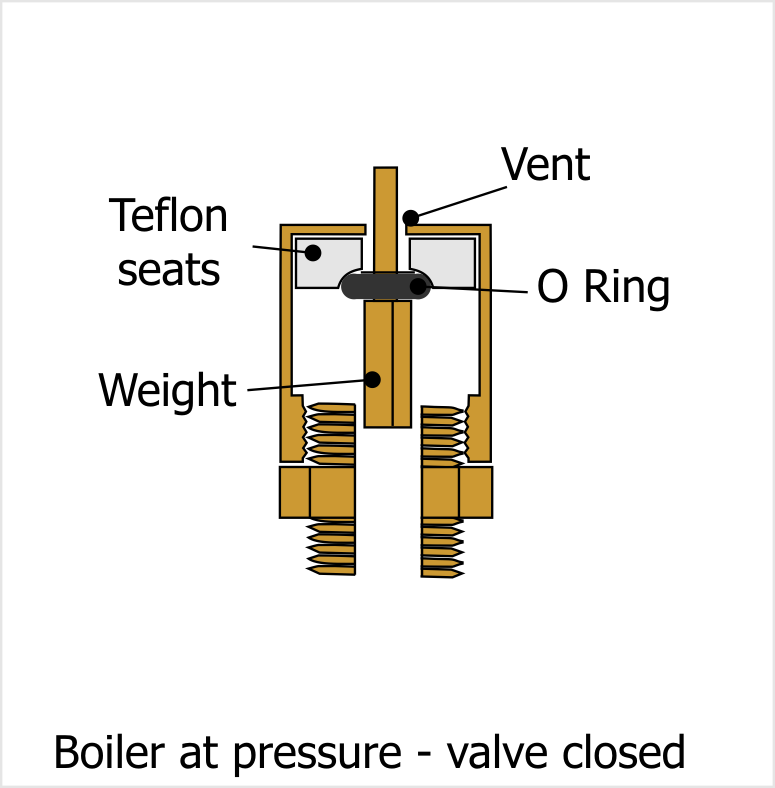

As you can see from slide 2, the internals of the anti vacuum valve contain just a few components. As the steam pressure inside the boiler builds, it lifts the weight up causing the o'ring to seal against the Teflon seats inside the valve. The weight is gauged so that the valve will drop when the pressure inside the boiler is unable to hold it closed.

After switching your machine off at the end of service, sometimes the anti-vacuum valve can be left stuck in the closed position, over night the steam in the boiler will cool down causing the boiler internals to be full of pressurised air. When you then turn the machine on in the morning, the system thinks it is up to pressure and does not turn the element on until you open the steam arm and release the cold air.

This is simply a worn seal inside the anti-vacuum valve allowing steam to escape through the valve. The leak will get slowly worse until the valve is replaced. Leaking steam also means more expense to run the machine as the heating element needs to work harder to maintain pressure inside the boiler.