"Turn up the heat - An espresso machine would be pretty lame without steam or hot water"

Before your espresso machine becomes a useful item of equipment for your business, it needs to be able to generate steam and hot water at the correct temperature and also the correct pressure.

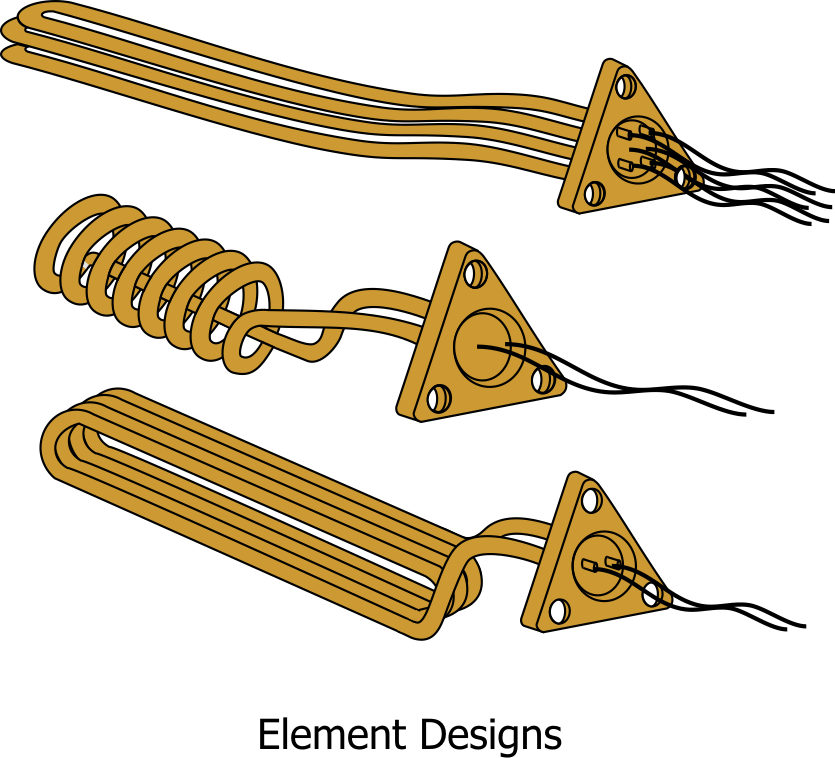

This is achieved using an electrical heating element that is located inside the machines main boiler and controlled by the machines control circuits.

Control of the element is by either detecting the pressure inside the boiler or by the temperature inside the boiler.

Pressure sensing method:

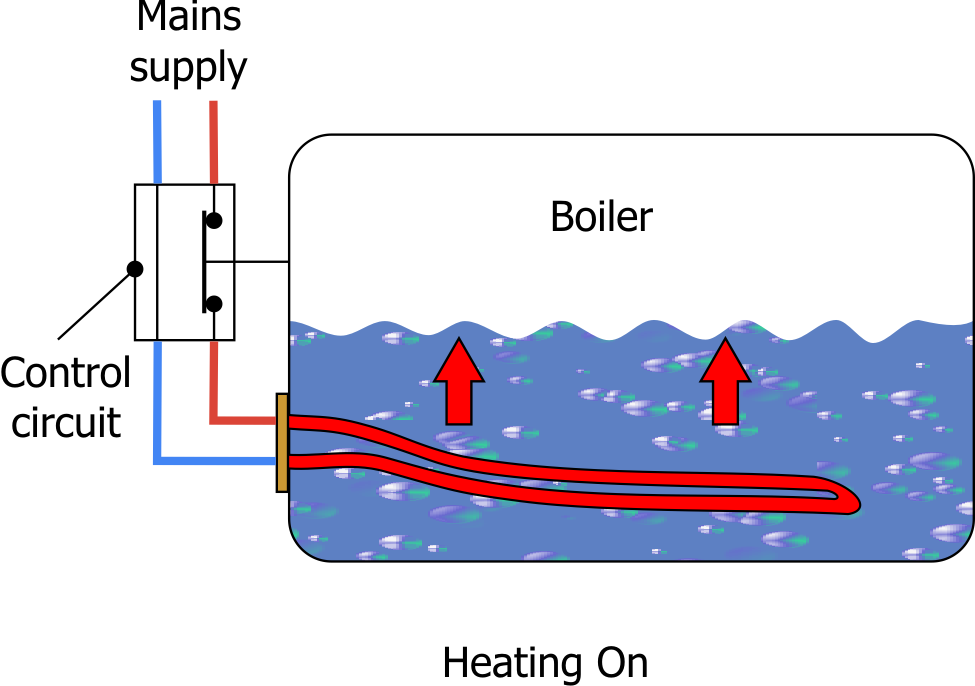

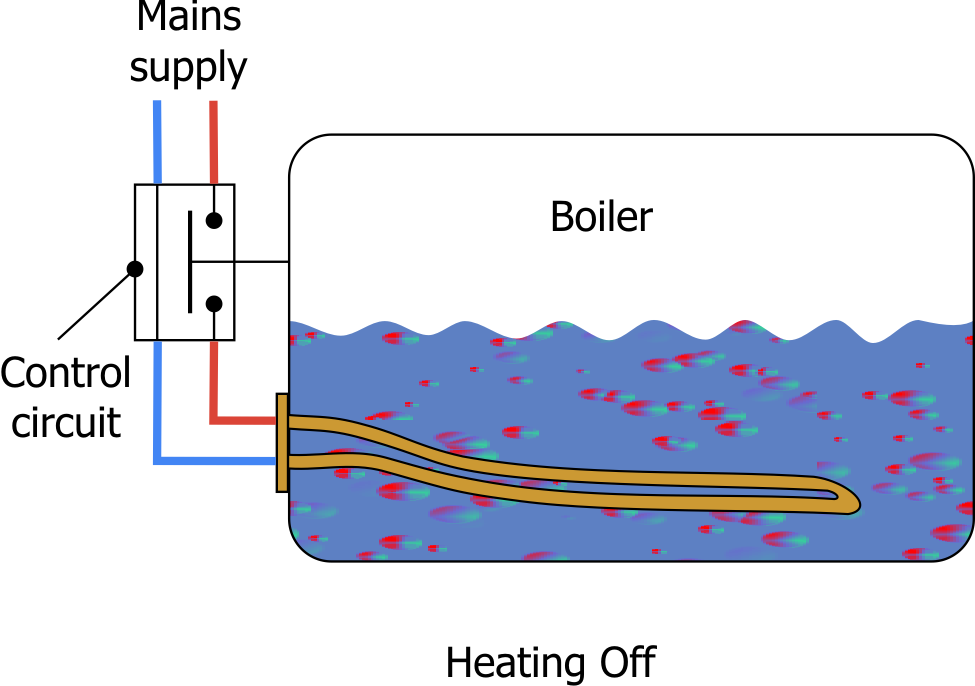

A feed pipe from the top of the boiler is connected to a pressure switch, when there is no pressure inside the boiler, the contacts on the pressure switch allow electricity through to the element, once the set pressure is achieved, usually set to 1 bar, the diaphragm expands inside the pressure switch and opens the contacts which cuts off the electrical supply to the element.

For: simple mechanical operation.

Against: due to the mechanical operation there is a wide swing in switching points.

WithTemperature sensing method:

This control method requires advanced electronic circuits, and by means of a temperature sensor mounted towards the top of the boiler. The sensor feeds back information to the main control circuit which then sends a signal to either a relay or a solid state device to switch electricity through to the element.

For: very precise control of the boiler heat. Lower energy usage.

Against: more costly control circuit.

Machine is switched on, if the pressure switch or the temperature sensor is calling for heat then electricity is supplied to the heating element.

Once the machine has reached the correct operating pressure, the electricity is removed from the element and the circuit stays in that state until until the machine detects either a fall in pressure or a drop in temperature.

The cycle above will keep repeating until the machine is switched off.

Once that you have checked the control circuits to the element and found them to be correct, we then need to check the element itself. Most likely fault would be an open circuit element. A continuity check using your meter should solve this.

If can switch your machine on and it seems fine until the heater kicks in, and then the breaker trips on the mains supply or blows a fuse. Then this is down to a short circuit on the element itself. Normally one leg of the element will have blown (maybe due to drawing too much hot water from the boiler), A meter will show low resistance between earth and one of the element legs.