"Show me the steam - How we let the barista control the volume of steam for perfect milk and latte art."

For all your milk based drinks that you produce from your machine, you will require some form of control over the volume of the steam that is allowed out from the machine via the steam arm nozzle.

Traditional espresso machines achieve this function by using steam valves, of which there is a few designs.

Standard Steam Valve - shown in the diagrams below, and is the most widely used variant, allows great control with easy serviceability and low cost.

Lever Steam Valve - operation is very similar to the standard steam valve, and can be more comfortable in operation, however this is a more costly approach for the same results.

Automatic Steam Valve - a much more complex and expensive system that takes all the skill away from the barista, making it ideal for some locations where staff turn over is high. However, does not offer anywhere near the speed or versatility of the standard and lever type steam valves.

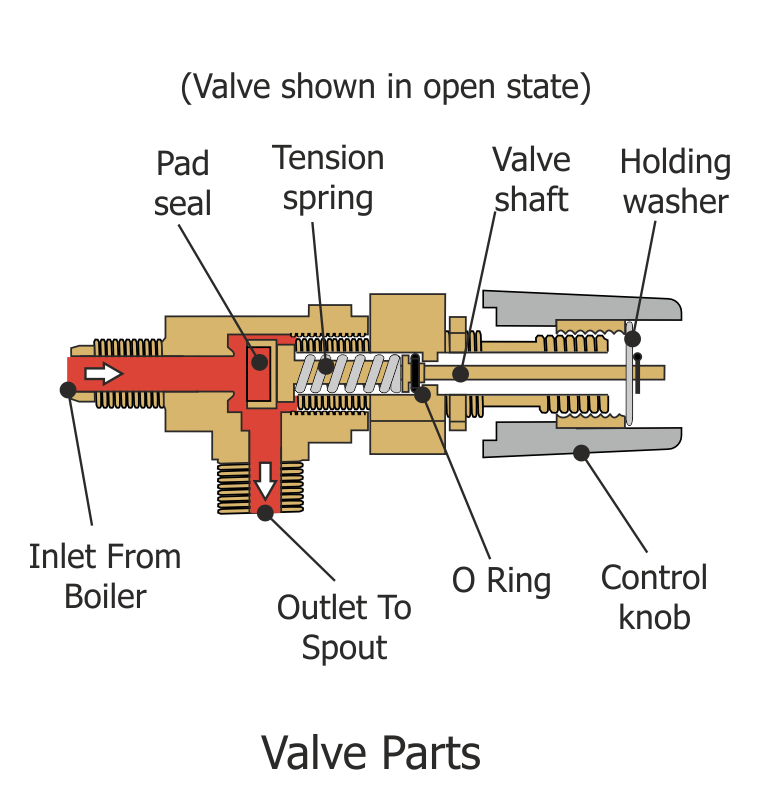

From the diagram on 'valve parts', you will notice that the valve shaft runs the length of the valve body connecting the control knob and the pad seal together.

When you turn the control knob in a counter clockwise rotation, the holding washer pulls the valve shaft outwards from the valve body, this lifts the pad seal and then allows steam from the boiler through to the steam arm. The more the pad seal is lifted, the more steam is allowed out of the steam nozzle.

After steaming is complete, turning the control knob clockwise causes the tension spring to expand and force the pad seal to close the valve.