"Drawing a cup of hot water - Yes its hot water, but not as you know it, learn why its available and how to use it."

Espresso machines have been around since 1884, but the very early models did not have the function to produce hot water, as the main design goal was purely espresso.

With the variety of beverage drinks expanding over the years, machine manufactures added the hot the water facility for drinks like Americano and long blacks.

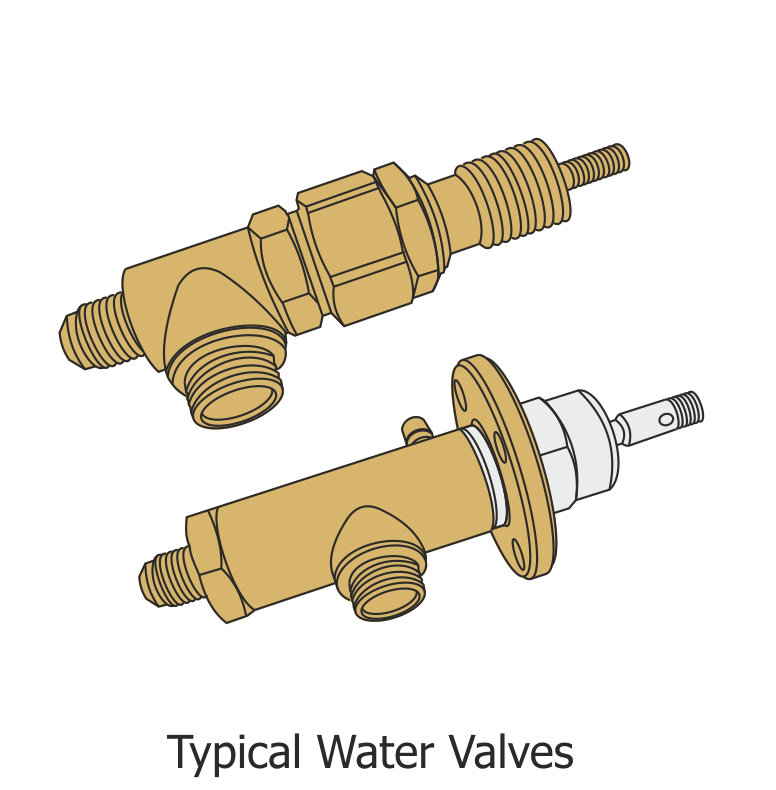

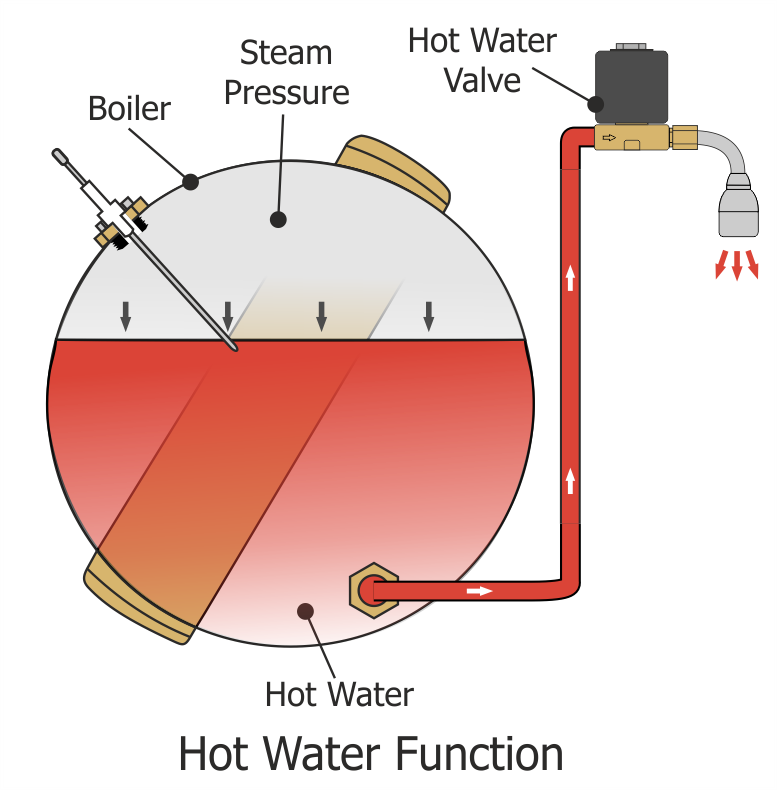

Hot water from your machines main boiler is forced out by using steam pressure, and there is 2 ways that we can use to control the flow of the hot water:

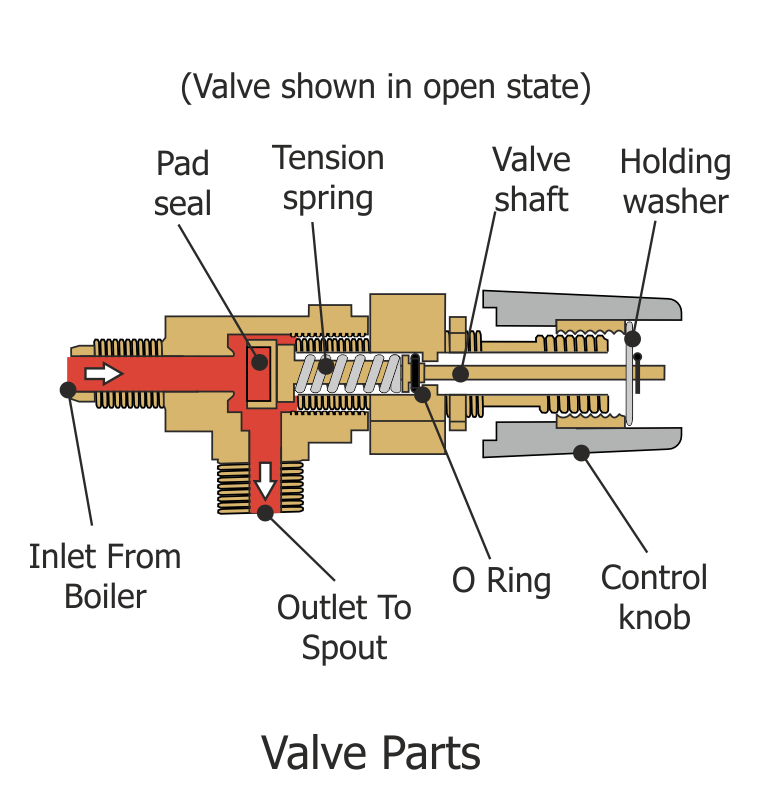

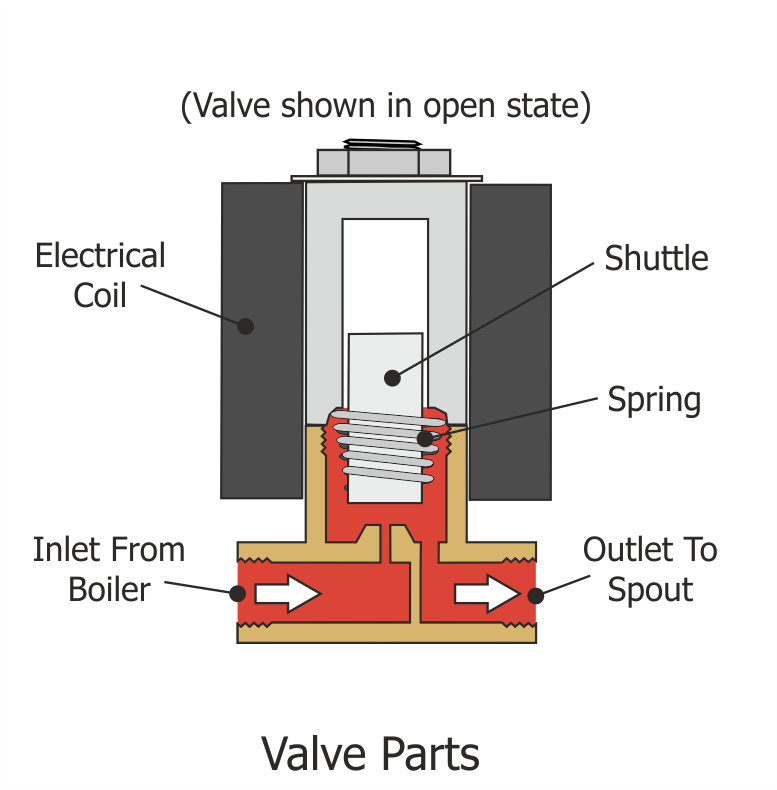

Manual Valve - normally a turn to operate valve and simple design with low maintenance cost.

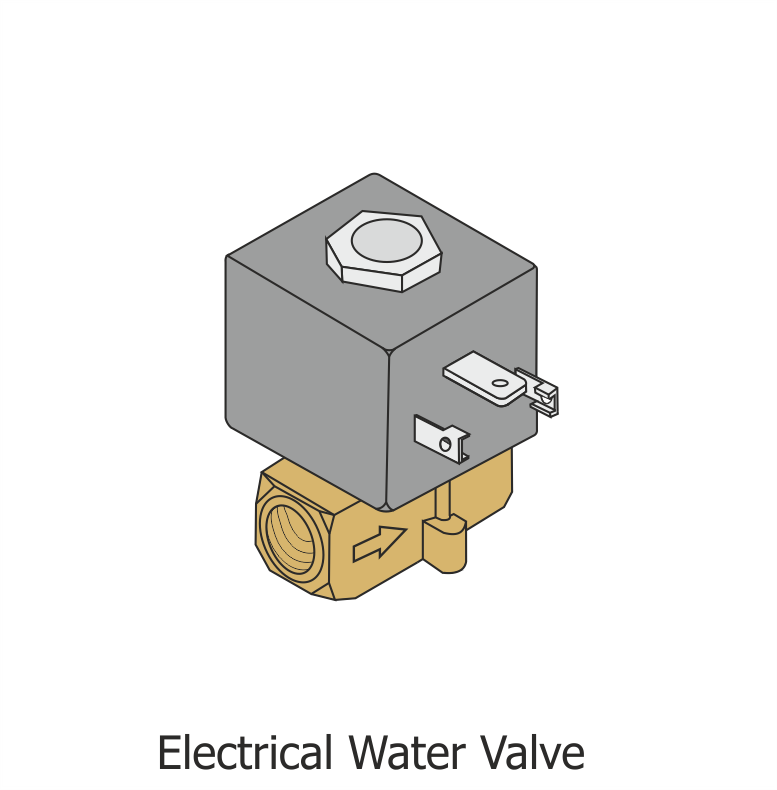

Electrical Valve - more expensive to employ on the machine, but offers greater flexibility with programmable dosing.

With the introduction of the hot water facility, salesman took the leap and started describing the espresso machine as a solve all solution. Whilst in reality, the hot water produced under pressure is not idea for tea, and a separate dedicated hot water boiler should be employed wherever possible.

Drawing large amounts of hot water off, also effects the efficiency of the machines heat exchangers and steam capacity.

Before any hot water is able to be drawn from the machine, the boiler needs to up to its normal operating pressure.

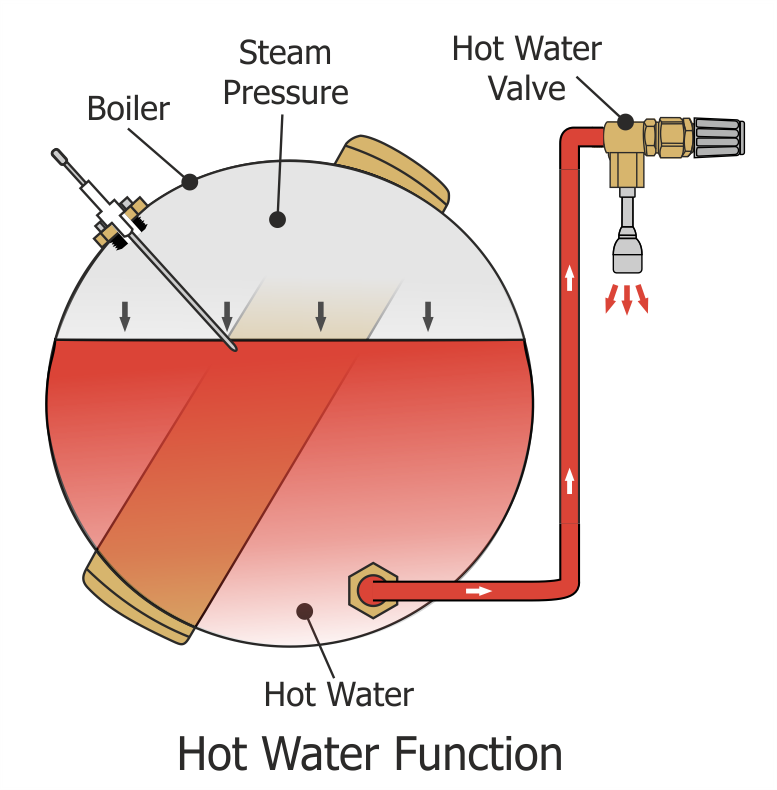

Once the machine is at pressure, water is drawn off the machine by simply opening the hot water valve. As the pipework that delivers the hot water is located towards the bottom of the boiler (slide 2), steam pressure is then used to force hot water through the pipework and out through the valve assembly.

Hot water will flow either until you close the valve or the machine runs out of steam pressure.

Before any hot water is able to be drawn from the machine, the boiler needs to up to its normal operating pressure.

As the pipework that delivers the hot water is located towards the bottom of the boiler (slide 2), steam pressure is employed to force hot water through the pipework and out through the valve assembly. Water is drawn off the machine by pressing the hot water button on either a stand alone switch, or a key on the keypad.

If the water is controlled via the keypad, then the control electronics will have been programmed to deliver a set time quantity of hot water.

Hot water will flow until you either stop the function or the machine does not have enough steam pressure to force water out.

Once that you have checked the control circuits to the element and found them to be correct, we then need to check the element itself. Most likely fault would be an open circuit element. A continuity check using your meter should solve this.

If can switch your machine on and it seems fine until the heater kicks in, and then the breaker trips on the mains supply or blows a fuse. Then this is down to a short circuit on the element itself. Normally one leg of the element will have blown (maybe due to drawing too much hot water from the boiler), A meter will show low resistance between earth and one of the element legs.