"Circulation dynamics - Thermal dynamics are not as scary as you might think, lets see how they work inside your machine"

The heat exchanger inside your espresso machine, is designed to perform two simple task in ensuring the brewing water is of the correct temperature. Which should be around 85-95 degrees Celsius for your chosen beans.

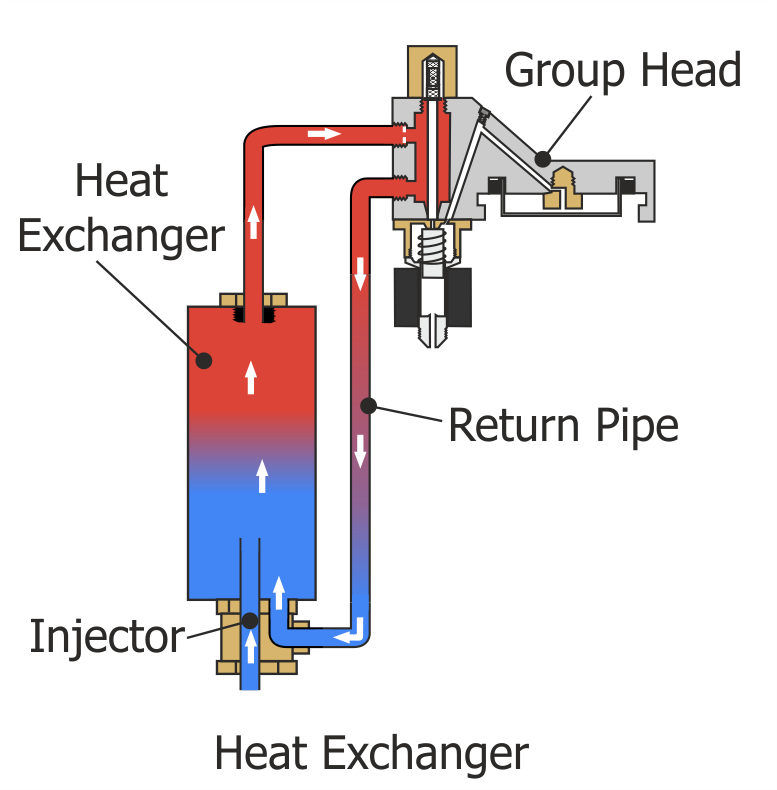

Its first task is to circulate water around the group head and maintain the correct brewing temperature,

Secondly, it has to heat up any fresh water coming into the group head to the correct temperature.

Both these task are carried out by the machine manufacture designing the system with the correct size and gauge of materials used in the heat exchanger and also the flow restriction in the group head.

As the system works on the principle of heat transfer, you will understand that any build up of scale inside the system will effect the brewing temperature of the water coming out of the group head.

Regular checks on the brewing water temperature will give you an indication of any potential issues and show that the filtration system needs attention.

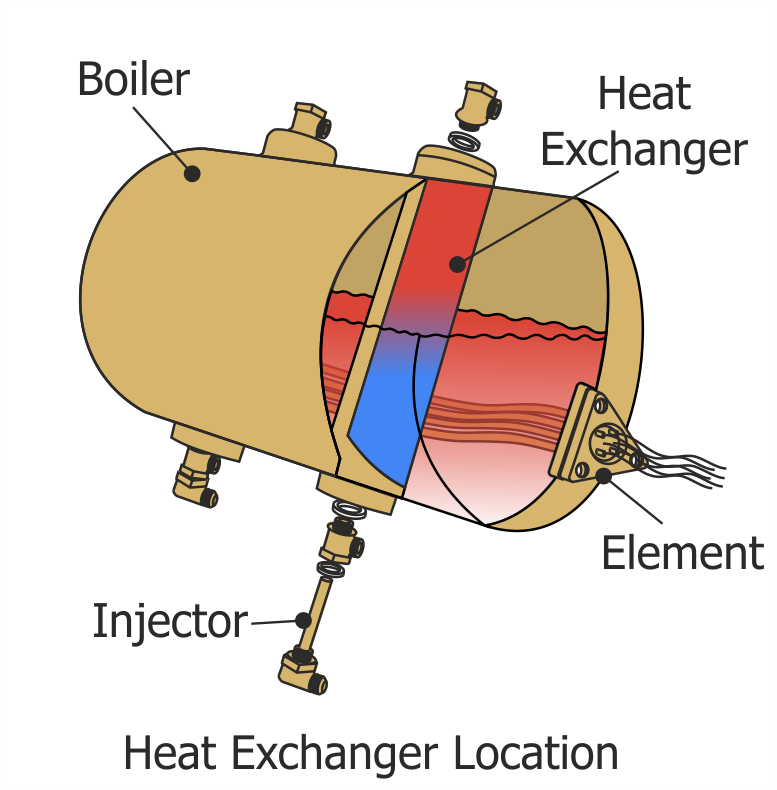

The heat exchanger inside your machine is contained inside the main boiler and consist of a tube that runs through the main boiler. As the water inside the boiler heats up to operating temperature, heat is then transferred through the walls of the tube and into the water held inside the heat exchanger.

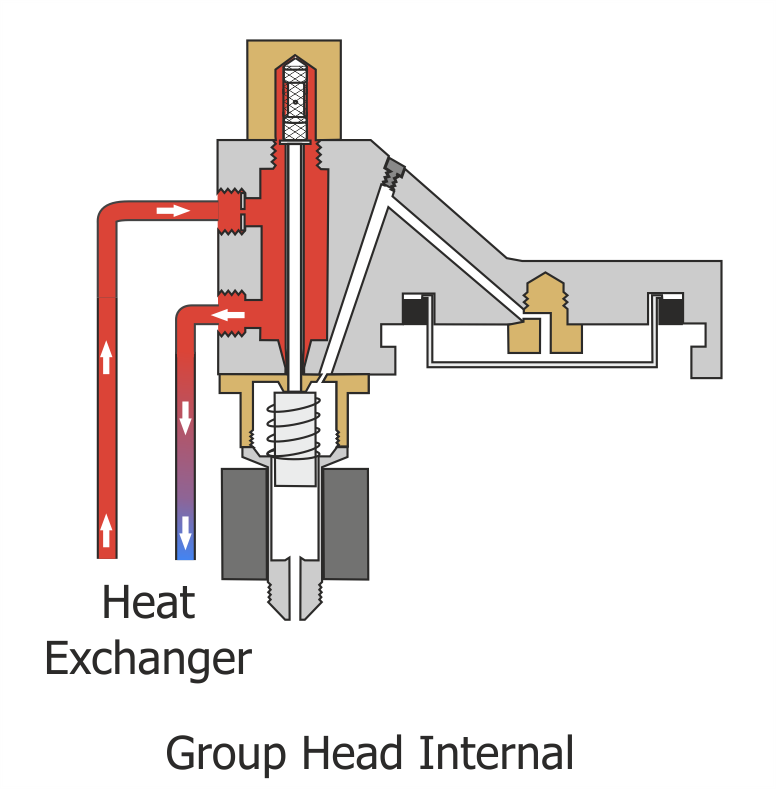

As the the water temperature inside the heat exchanger increases, it naturally rises towards the top of the group head, in the same way hot air rises. The group head is quite a heavy lump of brass, which causes this water to cool down as it circulates inside the group head.

Once the water temperature in the group head starts to fall, this cooler water then drops back down the return pipe and is returned into the bottom of the heat exchanger, ready for the process to repeat.

If you notice that over time your espresso shot coming from the group head is getting cooler, then the most probable cause is a build up of lime scale inside the heat exchanger due to an untreated water supply to the machine. This scale build up slowly thickens the walls of the heat exchanger and reduces thermal transfer from the boiler to the fresh water supplying your group head. A machine descale will need to be carried out to cure this fault.