"Getting the water to the grind - How we control the flow of water through the group head and through your freshly ground coffee beans."

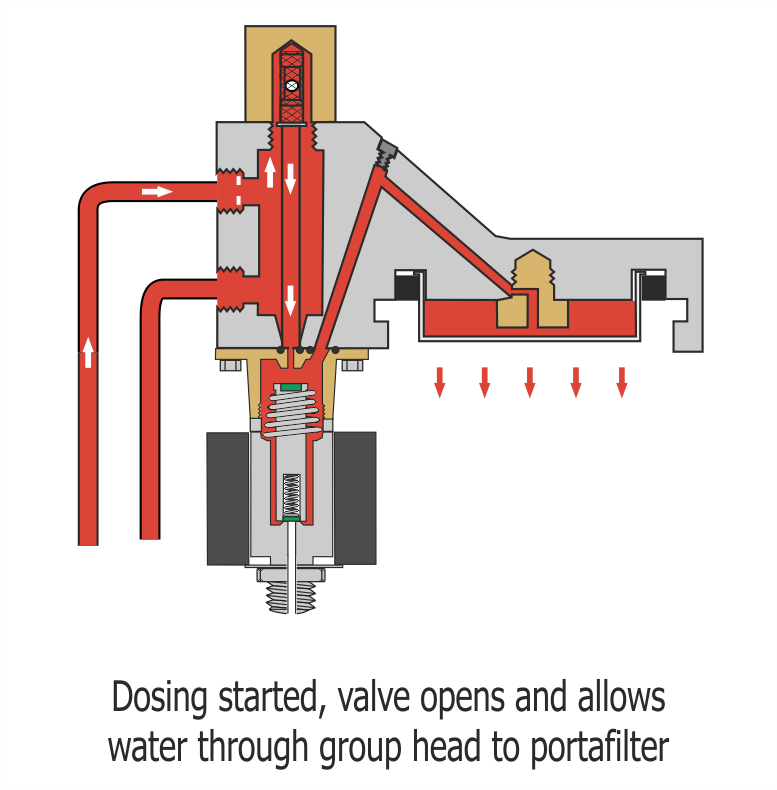

Now that you have seen how the flow of water travels from the mains into your machine, lets see how we allow that water out of the group head and into the portafilter.

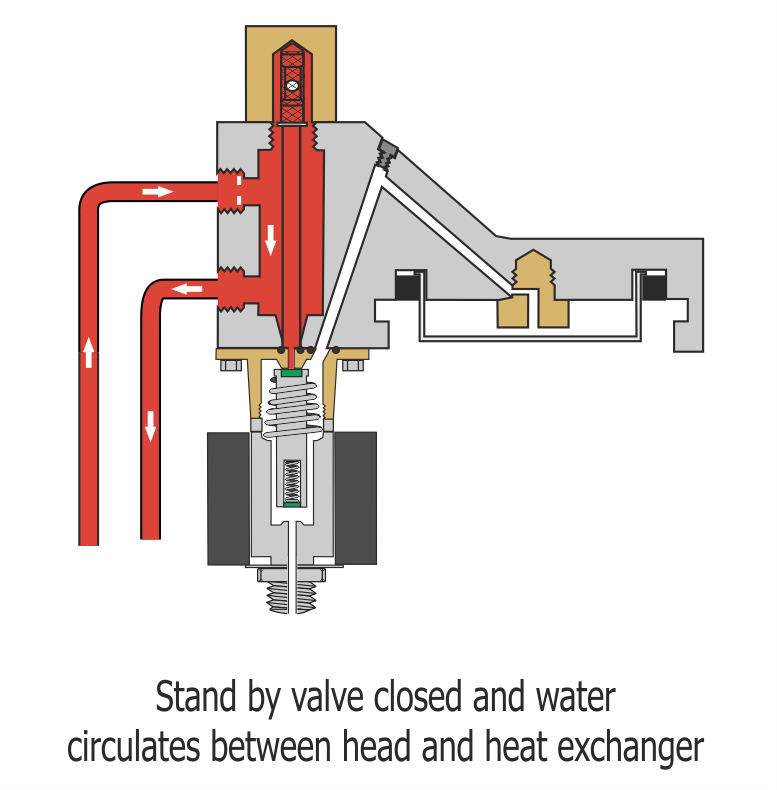

As you will have seen from the heat exchanger section, the brewing water circulates around the group head maintaining the correct temperature until its required.

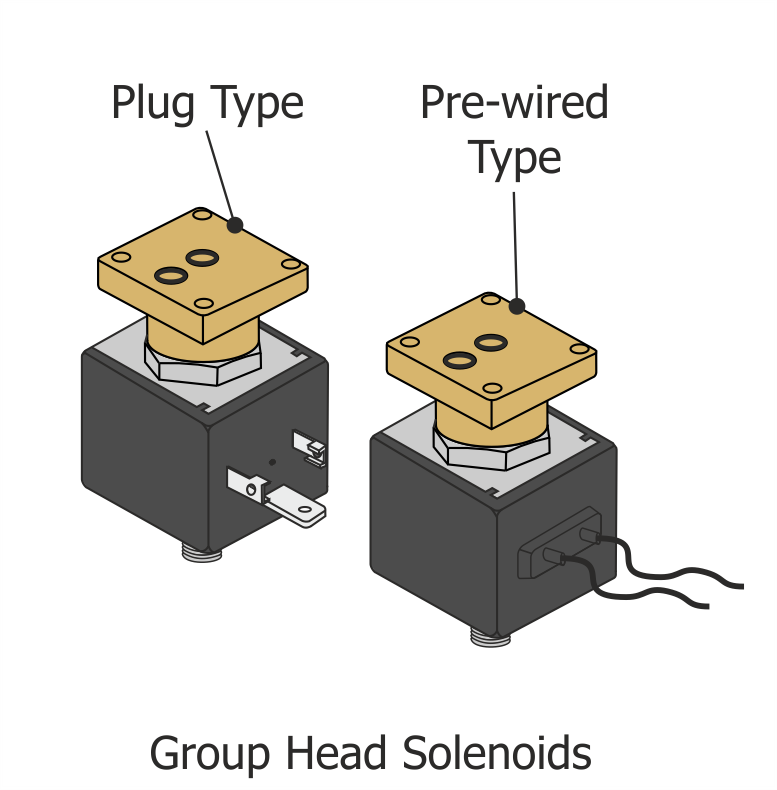

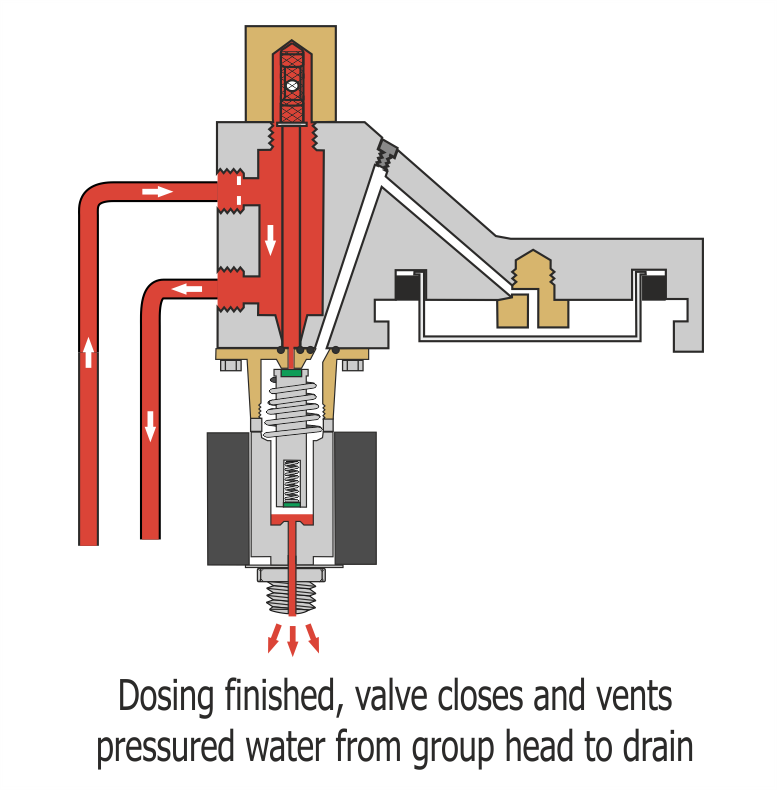

As the hydraulic section of the group head is a direct circuit to the mains incoming water, we use a solenoid valve to hold back the flow until required. This can either be called a group head solenoid or a 3 way valve.

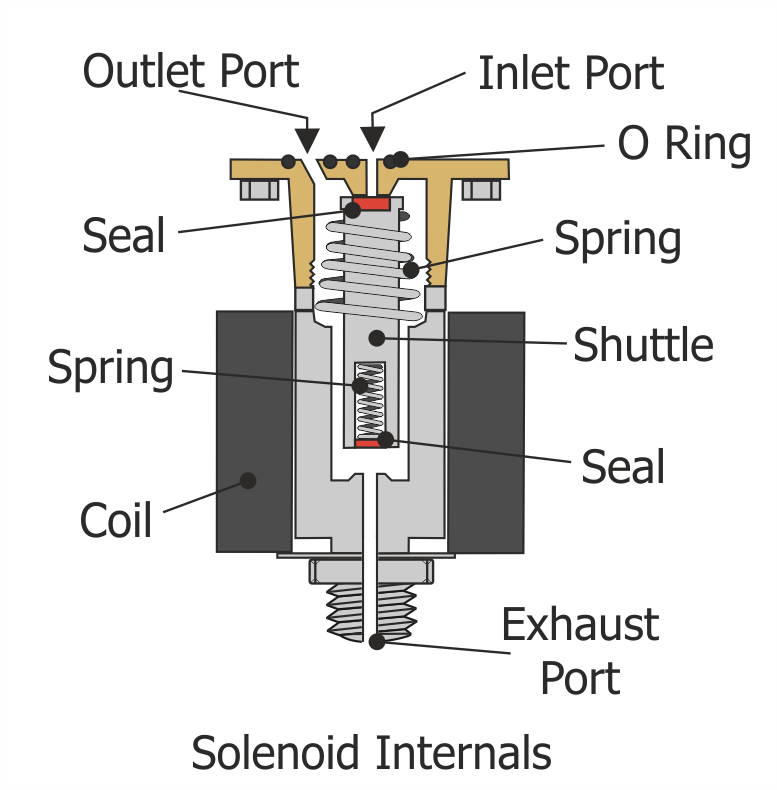

The term 3 way valve is arrived at, due to this type of solenoid having an inlet port, an outlet port and also an exhaust port.

The exhaust port is required on the group head, due to the pressure involved during the brewing cycle provided by the pump at 9 bar (130 psi), at the end of the brewing cycle we use the exhaust to remove the built up 9 bar pressure so that you safely remove the portafilter from the group head.

Whilst the machine is idle, the brewing water just circulates around the group head and heat exchanger (image 3), if the machine has been sat quite a time, then its a good idea to carry out a quick flush before making the coffee.

When you select a beverage, the group head solenoid opens and the pump starts running to increase the pressure up to 9 bar (image 4), the operation will continue until you either stop the flow, or the flow meter and control circuit reach the preprogramed level setting.

At the end of the brewing cycle, the machine then stops the pump and closes the group head solenoid which stops flow to the portafilter, as the solenoid valve closes the built up pressure in the group head is then allowed out via the exhaust port on the valve (image 5).

Short circuit on solenoid coil. Disconnect coil from control circuit to check. Replace faulty coil or complete solenoid valve with same type.