"Flow Control - Controlling the exact volume of your favourite brown liquid that goes into the cup, takes some clever tech"

So you want exactly 30ml of liquid gold in your cup, but unless you have a very accurate eye for measures, and the time to stand around watching, its a better option to allow the machine do the maths and the work for you.

Some older, or very cheap machines, only have a rocker switch to operate the group head, and believe it or not, there are some baristas that still prefer this method of operation.

With machines available with or without, lets take a look at the difference between the 2 models:

With flow meter - most modern machines employ this method and creates very accurate measures in the cup and consistent quality.

Without flow meter - more labour intensive and random levels in the cup, which causes variations in the beverage quality.

Its not hard to see the greater benefits of buying an espresso machine that includes flow control using flow meters.

You also get the benefit of multi button control on the group head giving you the option of different cup levels depending on the type of coffee you are making.

When you select a beverage selection from the your machines keypad, the following sequence of event will take place with instructions from the control circuit:

Group head solenoid opens which allows the flow of water through the machines hydraulic system.

The machine pump starts to run to pressurize the water and force fresh water into the system.

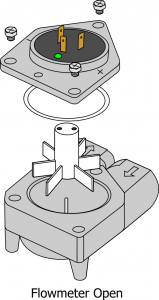

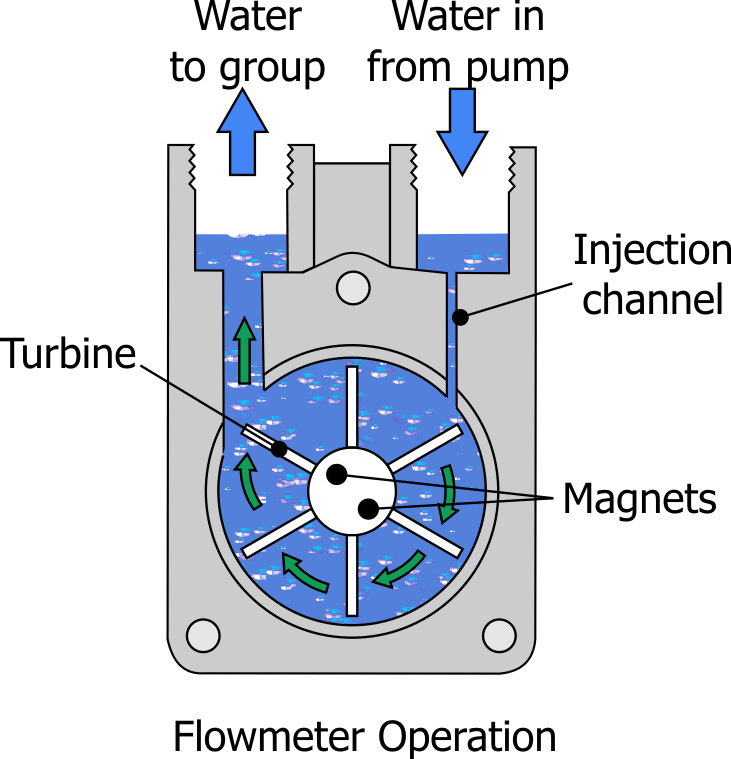

Water from the pump is forced through the flow meter body injection channel causing a jet of water to push the vanes on the turbine.

The turbine inside the flow meter spins and the magnets on the top of the turbine operate a sensor which sends electrical pulses to the control circuit.

Once the preprogrammed amount of pulses are received, the control circuit then stops the pump and switches of the group head solenoid.

Flowmeter is not emitting a signal to the control board, which could be caused by debris inside the flowmeter, if you can see the top of the flowmeter during operation, you should be able to see the LED blinking as the group is running. If the flowmeter is clean and no LED is flashing during operation, then a new flowmeter may be required.

If your machine appears to shut down during group operation, the fault may lay with a faulty flowmeter being short circuit and drawing too much current from the main control board. A quick test is to disconnect the flowmeter wiring and if the problem stops, replace the flowmeter. This happens as the main control boards have only limited current supply.