"Blowing of steam - We all need to let off a little pressure from time to time, and your machine is no different"

With an average espresso machine boiler working around the 1 bar pressure range, we need to have safety devices in place just in the event that something goes wrong.

This is where our trusted safety valve comes into play, and in the event of a control circuit failure it will operate and release any excess pressure which stops the machine from exploding.

It is important to note that the pressure safety valve should be replaced on a yearly basis to ensure continued protection.

PSSR regulations cover the safety at work guidelines for pressurized equipment within the UK and full guidelines can be found here at HSE

Depending where you are, some local authorities or your insurance company may insist on you having written schemes and boiler inspections in place.

This work can be provided by a locally qualified espresso machine engineer, there will be an index here shortly.

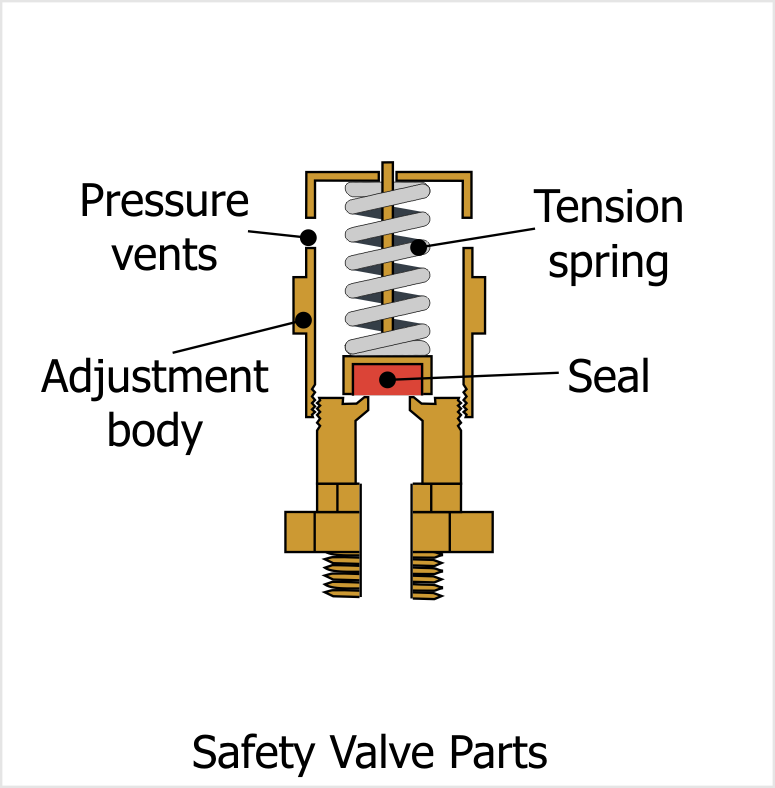

Under normal operation the control circuit on your machine regulates the pressure inside the boiler between 0.8 and 1.1 bar depending on settings. Steam is retained in the boiler by the seal inside the valve.

The safety valve is calibrated to operate around the 1.6 bar region to allow for for slight variations in pressure, the calibration of the valve is achieved by rotating the adjustment body on the valve and this function is normally carried out by your engineer during the annual boiler inspection. Clockwise rotation increases the resistance on the tension spring which increases the pressure required to open the valve and vent the boiler.

If the pressure inside the boiler reaches the 1.6 bar set point, the spring starts to open (sometimes with a pop) and excess steam is released through the pressure vents on the valve.

Visible signs of steam leaking from the top of the machine, or you can hear a hissing noise, could indicate a leaking safety valve and should be addressed quickly. This part should only be replaced by a certified valve and should be tested for operation afterwards.